Application Specific Cutting Tools

Shape-Master Tool specializes in the manufacturing of PCD and PCBN custom tools. Machining with a custom tool designed by one of our application engineers will often lead to reduced machining times, improved tool life, limited changeover, and optimal finishes on the part being machined. This results in saved time and costs as well as a superior finished part. Our engineers will provide you a cutting tool optimized for you application.

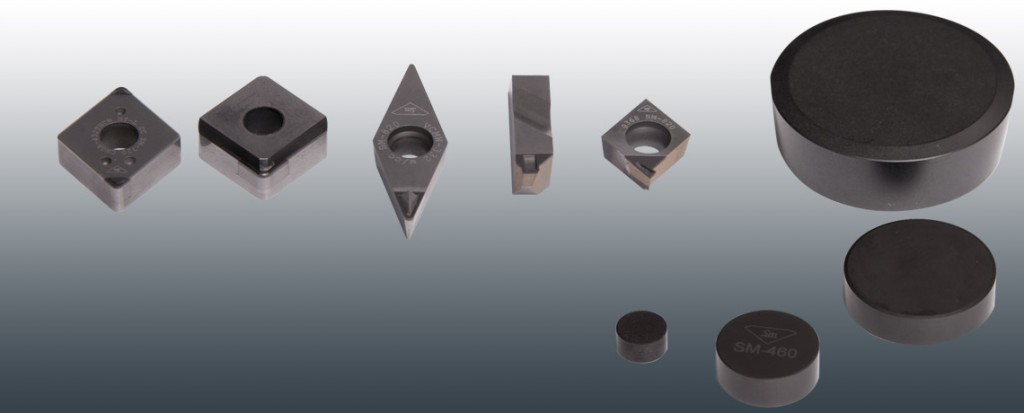

PCBN (Polycrystalline Cubic Boron Nitride) Cutting Tools

PCBN, also known as CBN cutting tools are used most commonly in the machining of extremely hard and/or abrasive materials. We offer a large selection of PCBN grades designed specifically for the material being machined and your part and process requirements.

Typical PCBN Cutting Tool Applications:

Powdered Metals

- Heat Treated

- Sinteredhardened

- As-sintered

- Steam Treated

- Copper Infiltrated

Steels > 45 Rc

- Alloy Steels

- Tool Steels

- Bearing Steels

- Die Steels > 30 Rc

Cast Iron

- Class 30+ grey irons

- Hardened / White Irons

- Ductile Iron / CGI

Tungsten Carbide

- > 15% Binder

Super Alloys > 35 Rc

- Nickel Based

- Cobalt Based

Hardfacing alloys

- Thermal Sprays

- Spray & Fuse

- HVOF / PTA coatings

PCD (Polycrystalline Diamond) Cutting Tools

PCD tools are typically used in the machining of abrasive, nonferrous metals and other non metallic materials. With a variety of PCD of grades available our application engineers will match your application with the best PCD grade to optimize your machining needs.

Typical PCD Cutting Tool Applications:

- Aluminum Alloys

- Tungsten Carbide

- Cold Sprays

- Copper Alloys

- Metal Matrix Composites

- Plastic / Fiberglass

- Titanium

- Thermal Sprays